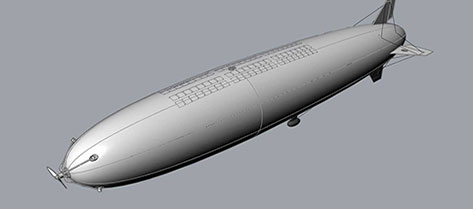

Reduced aerodynamic resistance index and increased maneuverability

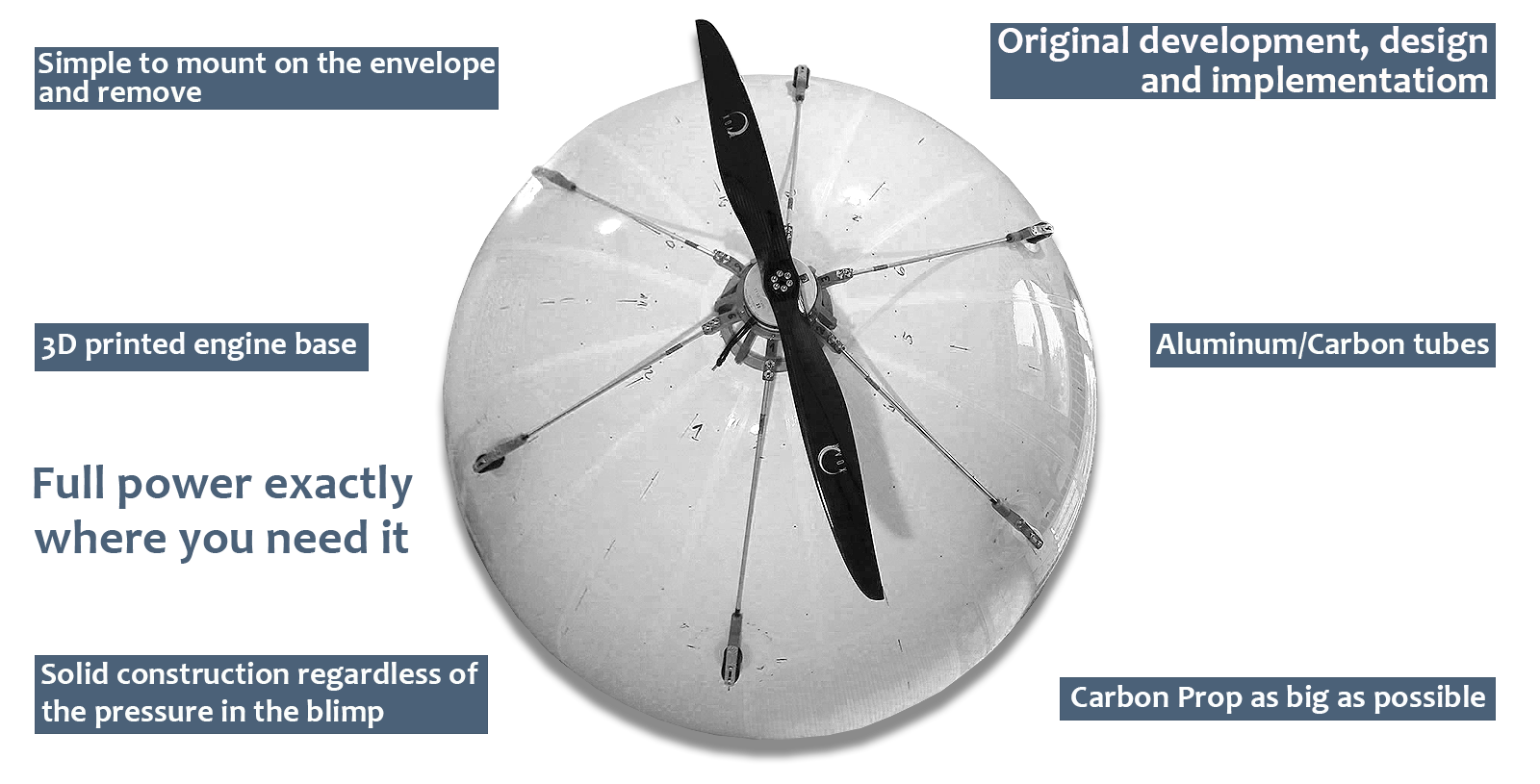

Innovation and originality: One main engine is mounted on the "nose" of the UniBlimp, which creates overpressure and reduces front drag.

A simple solution after years of experimentation and development

Reduced energy consumption

Thanks to the previous work on the T-Blimp, the results showed us that placing the main engine in the horizontal axis of the blimp has the best energy transfer with the least losses

Higher maneuverability

Since the resulting design is the largest possible distance between the drive motor and the control surfaces, the minimum displacement of the aileron strongly deflects the UniBlimp in 3D space

Longer autonomy

As a result of all the radical changes (relocating the engine to the nose, large distance between the engine and the stabilizer, and a radical reduction of the necessary electronics and components,...) we got a far greater flight autonomy than with the classic Blimp design.

uniblimp

Easy to RC control

The following energy savings as well as increased maneuverability were obtained with a large distance in the position of the engine and stabilizer on the envelope. The greater the distance, the greater the sensitivity.

Reduced weight - reduced volume or the same volume - greater load capacity

Since we reduced the total weight of the components to a minimum - for the same volume, we can have a higher load capacity. This is extremely important in order not to jeopardize the ratio of the length and width of the envelope and thus increase the aerodynamic resistance. The less resistance, the better the flight of the Blimp.